Consistency Efficiency Scalability

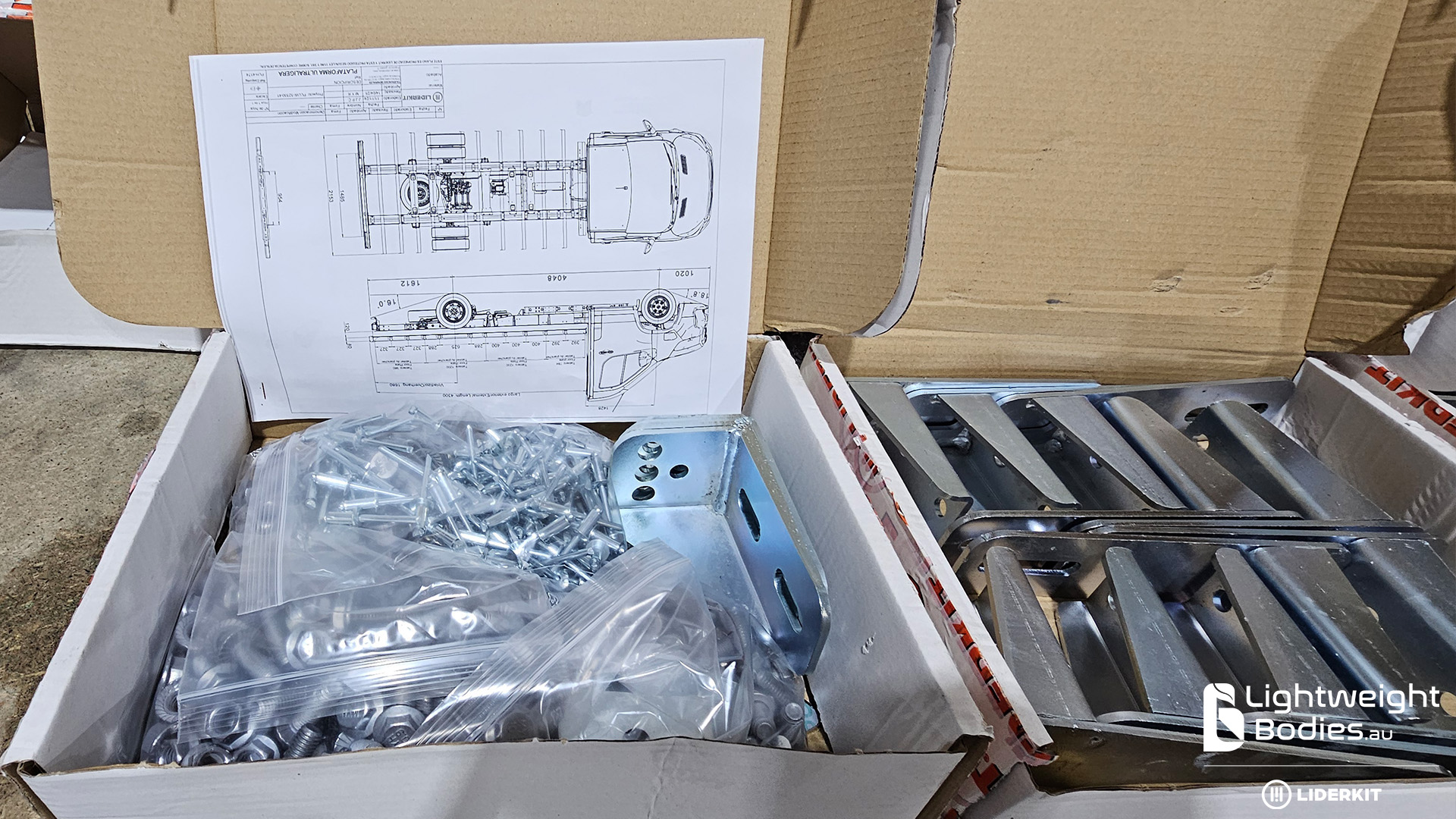

We provide comprehensive engineering drawings, eliminating the need for costly engineering services. This ensures that all our partners receive ready-to-use, detailed plans and instructions, saving time and reducing costs.

Our kits come complete with all required components, including nuts, bolts, rivets, and glue, removing the need for time-consuming procurement. This streamlines the assembly process and saves costs by eliminating waste.

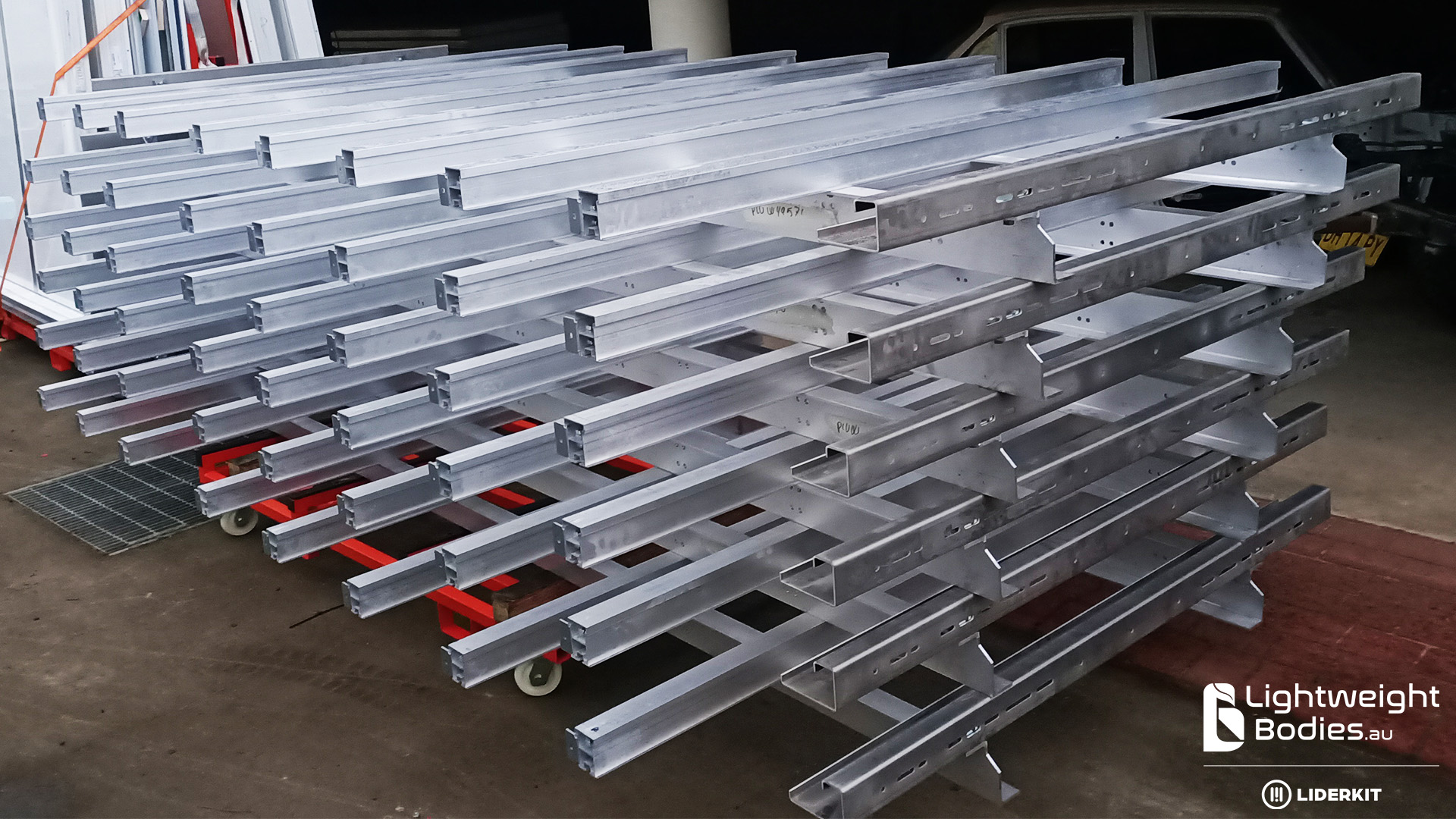

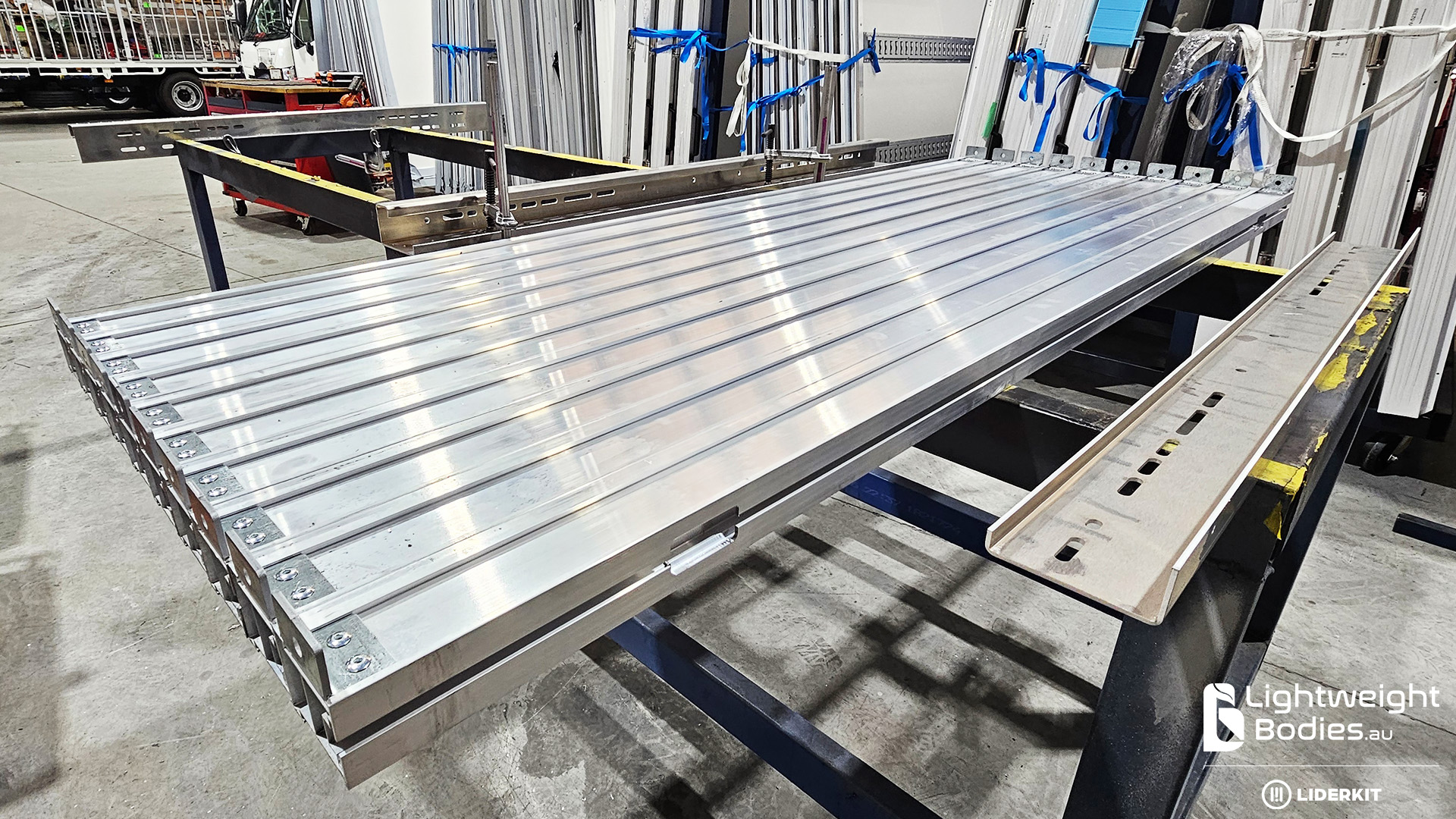

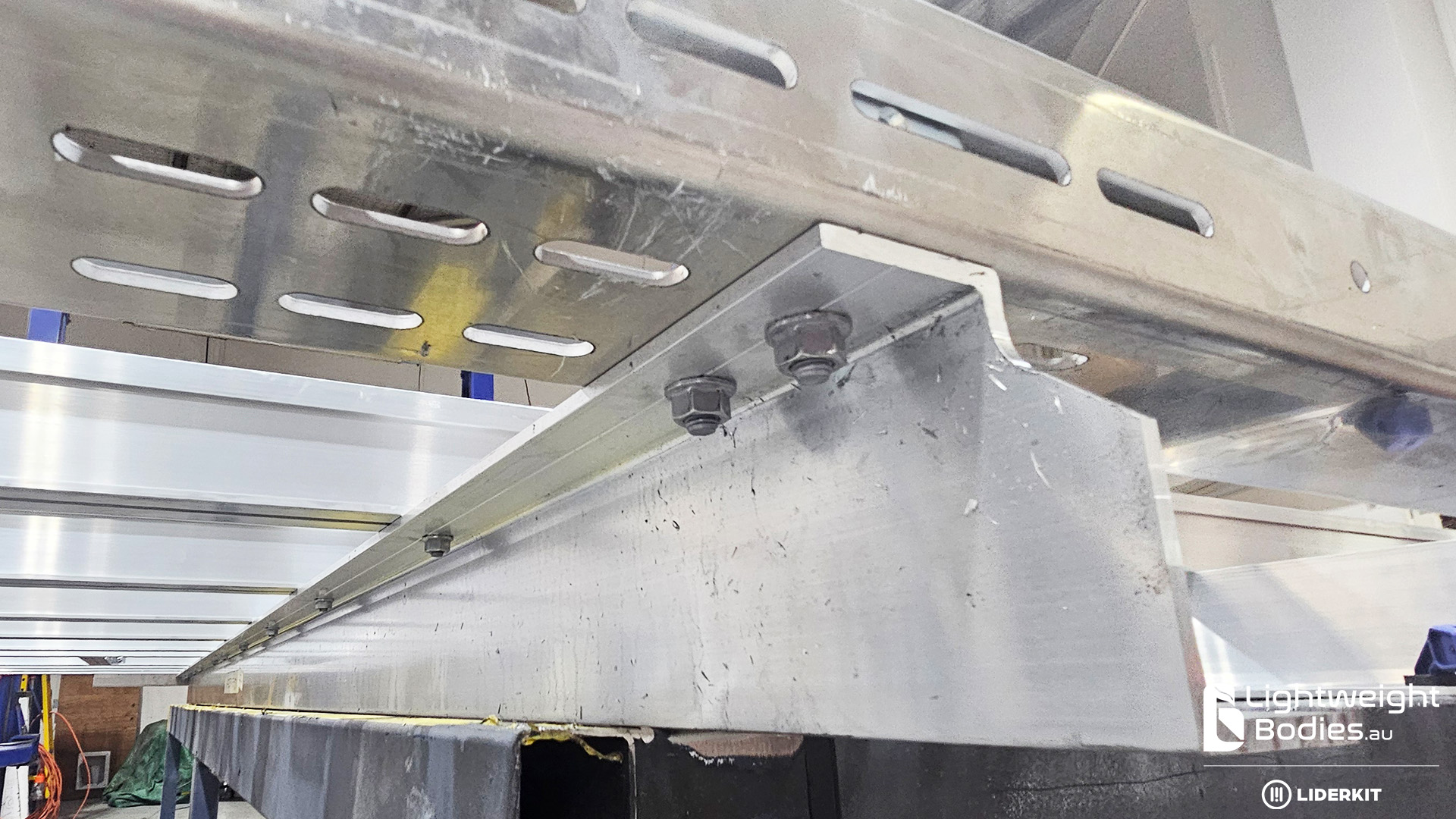

Our kits are designed for seamless assembly, with no material meassuring or cutting required. Every component is ready to install, reducing labour time and minimising errors compared to traditional bodybuilding methods.

Our kits require no welding. This eliminates the need for specialised welding skills, cuts down on consumable welding costs, further reducing labour expenses and speeding up the assembly process.

Our kits come fully finished with no painting required. Each component is pre-coated or treated, eliminating the need for additional painting services. This reduces both time and costs associated with paintwork, while ensuring a high-quality, durable finish straight out of the box.

Do More with Less: The Labour-Smart Solution

Traditional truck bodybuilding relies on scarce skilled labour, expensive trades, large workshops, and heavy equipment. Lightweight Bodies kits from LIDERKIT® flip that equation. Each kit arrives 90% complete — pre-engineered, pre-finished, and ready for fast assembly.

Here’s what that means for you:

One tradesperson can supervise 5–10 builds at once.

No welding, cutting, or painting required — assemble and fit.

Every component supplied — bolts, rivets, adhesives, and finishes included.

Minimal workshop space is required — efficient builds can be achieved without the need for sprawling facilities.

No heavy or expensive machinery needed — straightforward assembly reduces overheads.

By stripping out complexity and waste, you can scale faster, lower costs, and keep trucks rolling. More than a solution, our kits become a key advantage in your product range — giving you the ability to deliver faster, more reliable builds that stand out in a competitive market.

Seemless Assembly – From Start To Finish

Traditional build (4300 Pantech): 115–125 hours — cut, weld, paint, elec, and fit.

Lightweight Bodies kit assembly: 25–30 hours — no engineering, no procurement, no welding, no painting.

4× faster, with lower labour costs, minimal floor space, and access to a broader labour pool.

The result?

Continuous improvement.

Reliable outcomes.

Every build.